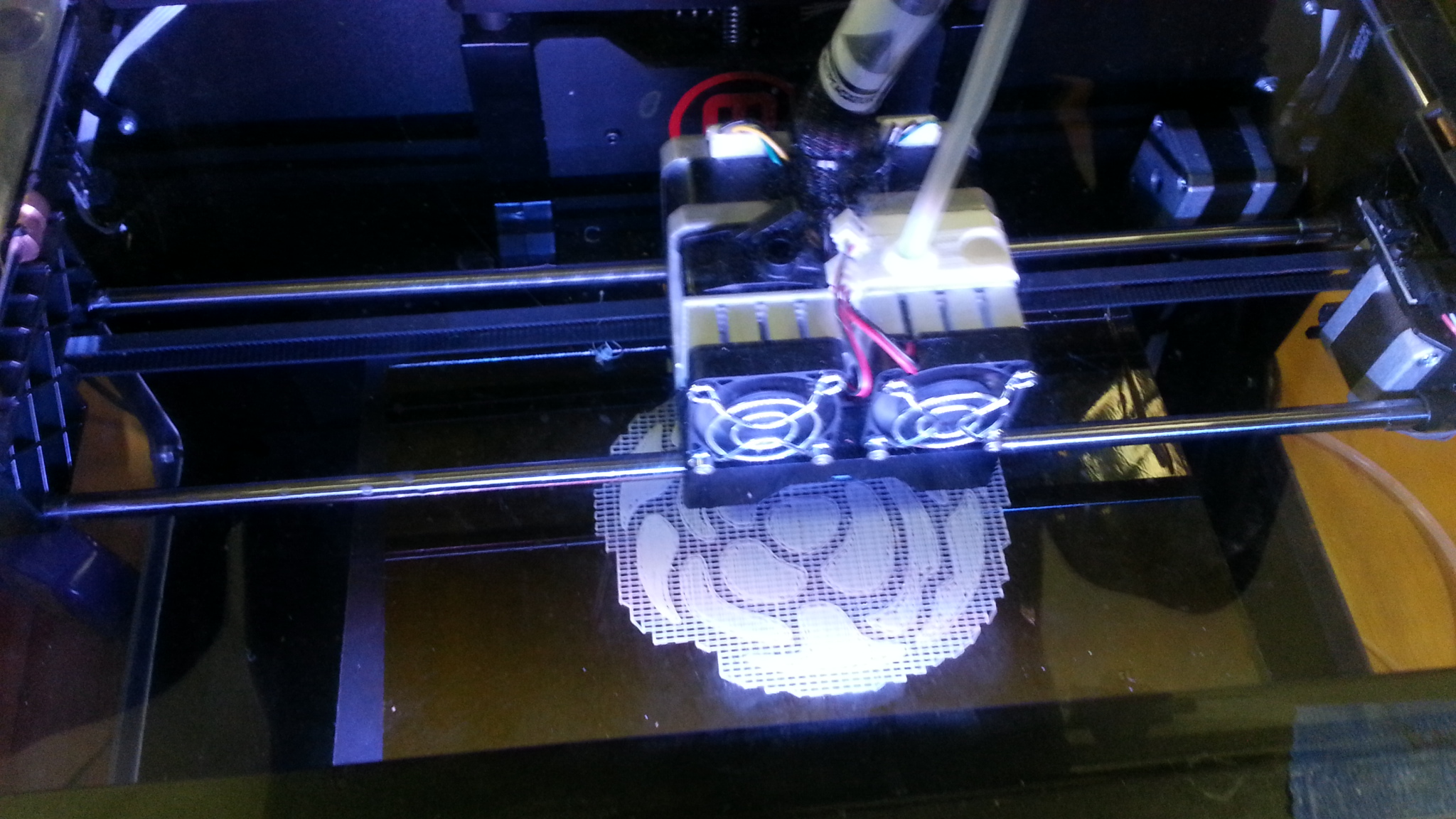

3D printing in india was initially quite stagnant, but a sudden boom in 3D printing startups has created a whole culture of 3D printer industries. Most of the Indian startups aim to make a cost effective 3D printer. While they currently aim at industries, they will soon design products for regular people as they try to make their printers cheaper. As of right now, our economy prefers cheap over high quality.

The reasons for regulating 3D printers have been covered by Kartik in his post

here. As mentioned therein, the main reason why it is almost impossible to regulate 3D printing is because the =&0=&So the users can modify the operating system and the hardware of the printers to use them however way they want. They can even add parts or remove parts as 3D printers are generally quite customisable, with many how-to guides on the internet.

A general rule of thumb for hacking is that it is tougher to hack something if you don’t have the hardware, but it gets very easy if you have the hardware. The people with the know-how can easily remove the restrictions put in by the manufacturers, no matter what these restrictions are. These people will then release guides, allowing other people to to do the same.

=&1=&

* Websites selling 3D printed guns/other illegal commodities.

* Websites selling 3D printers capable of creating illegal commodities.

* Restrictions on the materials (plastics , metals , ceramics etc), so people buying these in large quantities could be possibly manufacturing illegal things in government’s eyes.

That is where I think

this article is slightly off the mark. In its discussion of the ‘Reliability’ point, the author therein says that 3D printers typically use plastics. While that is currently true, that is because plastics are relatively cheap, and 3D printing is still practically in its infancy. But it is also technology that is quickly gaining funding. Thus, while plastics, being cheap and easy to manufacture, are used as of now, it will soon be quite easy to use metal and other forms of inks. It is not currently cost effective, but the growth of 3D printing industry

will be exponential.

According to me, it is not possible in any way to put a restriction on 3d printers after they are bought. Only on the outlets that sell the printers and the quantity of material sold can there be possibility of successful restriction.

=&2=&

* Closed source : The underlying code of the 3D printer is hidden, making it extremely hard, but not impossible, to find loop holes even for experts. To bypass this most people will just replace the full operating system with a custom version.

* DRM on purpose-built hardware/similar schemes : It is tough to build the hardware to protect the secret key against a sufficiently determined adversary. This is the restriction we should expect in commercial 3D printers.

* Software based DRM/similar schemes : This form of restriction is usually easy to break, as the decryption keys would be present with the software for decryption of the content.

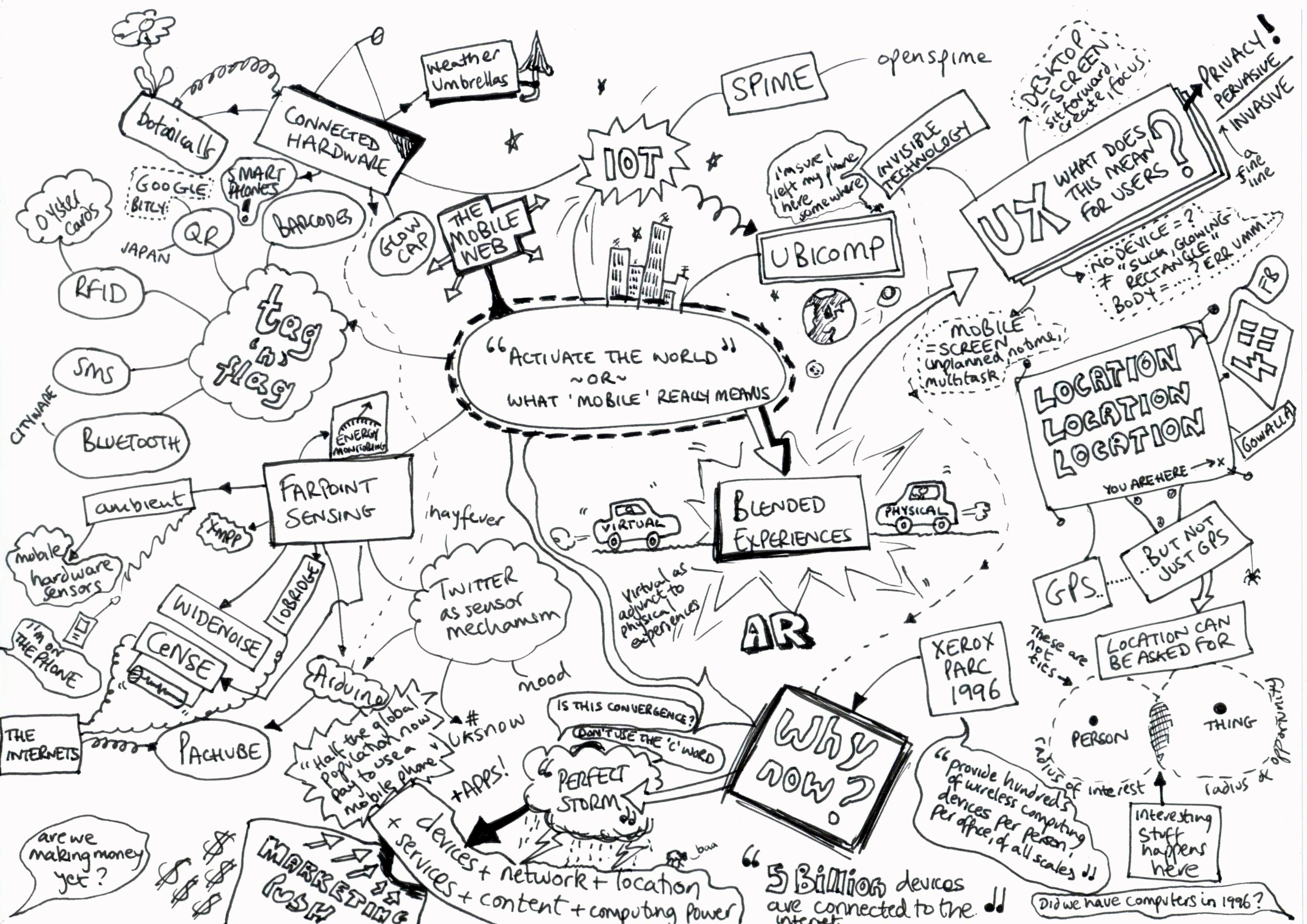

As a side note, an interesting concept is that of 3D printed cars. The convergence of the automotive industry with 3D printing technology is quite powerful an idea. At an individual level, it will be possible to download car’s design, print it, drive it. But at the industrial level, this (extremely exciting) technology is still in its infancy, and it won’t achieve its true potential until the automotive giants bring their capital, and their excellent R&D departments, to invest in the technology themselves.